With increased demand for efficiency and performance in the next generation of engines, precise measurements are of critical importance. Adcole gages are up to the challenge.

Gage Types

A Solution For Every Challenge

Aerospace

Strict part quality requirements, traceability and easy data collection capabilities are why Aerospace companies turn to Adcole gages as their metrology solution provider.

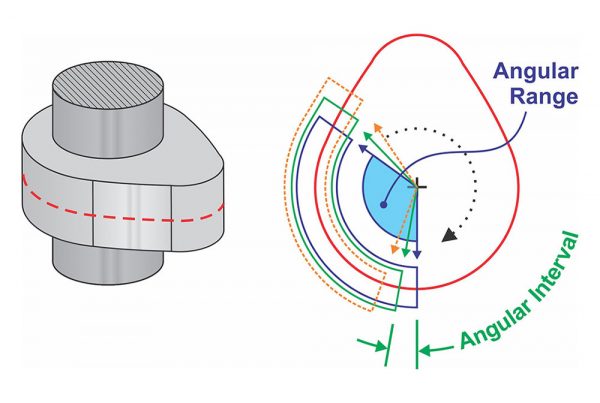

Angularity

Angularity describes the specific orientation of one feature to another at a referenced angle.

Automated Gage Systems

Automotive

Automotive manufacturers face high throughput demands while delivering peerless quality, often requiring 100% inspection — that’s why they rely on Adcole in-line and audit lab gages to ensure that sub-micron accuracies are met. From fundamental dimensional measurements to chatter and lobing — Adcole provides solutions including automatic data collection and part traceability.

Avg Max Height of Profile

The average maximum height of profile is a computation derived by taking an average as defined by the sampling of the maximum height of a component’s profile: this parameter is frequently used to check whether the profile has protruding peaks that might affect static or sliding contact function of a component.

Axial Location

Axial location is the measurement of where the central axis of a component is located when the component is rotated, in order to know if the rotating component is within parallel specifications. An angular error in the component will contribute to greater axial runout.

Axles

The automotive industry has counted on Adcole’s Trusted Accuracy to measure axles for decades, resulting in increased productivity, recognized quality and rapid return on investment.

Cam Lobe Lift Error

Adcole gages and software provide accurate data about camshaft lobe asymmetry with unmatched levels of repeatability.

Camshafts

Gage-to-gage repeatability ensures that camshafts and other parts are manufactured to identical standards/tolerances across the entire plant—or even company-wide.

Center Deviation

Center deviation is based on the three radial cuts of the lobe. It is the difference between the measured diameter of the center cut and the average of the diameters of the two outer cuts.

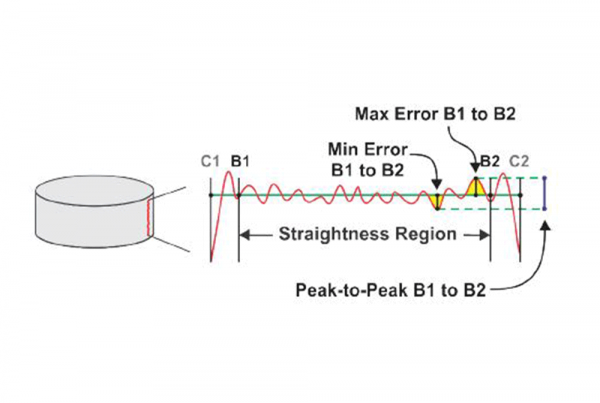

Chatter

When profile error of your cylindrical part has a repeating, undulating pattern, it is said to exhibit Chatter. Adcole gages provide chatter measurement to find the specific Undulations per Revolution and amplitude results for a recurring signal

Concentricity

Concentricity is a complex tolerance used to establish a tolerance zone for the median points of a cylindrical or spherical part feature. Concentricity is generally reserved for high-precision parts, and only when there is a need to control median points.

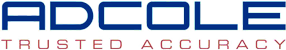

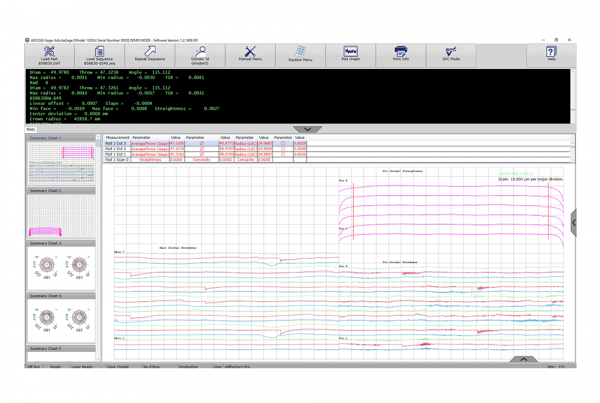

Crankshaft & Camshaft Measuring Gages

Adcole crankshaft and camshaft gages are designed to meet the demands of production lines while providing the very best in accuracy, versatility and reliability. Their ruggedness and superior repeatability set the standard in the world of metrology.

Crankshafts

With a large selection of gages that can accurately and efficiently measure crankshafts, Adcole’s optical metrology products are applicable in a wide array of industries.

Custom Shaft Gages

Adcole automatic and semi-automatic cylindrical coordinate measuring machines are known for their exceptional accuracy and high repeatability. We can design or customize a coordinate measuring machine for virtually any application to accommodate your production and quality control requirements.

Cylindricity

Cylindricity is defined as the difference between the maximum radius and the minimum radius of all three-journal measurements relative to the axis of the outer cuts.

Diameter

The measured diameter is based on a single radial measurement. The average of the radial readings of the follower is used to compute a best fit circle. The follower readings are summed up and divided by the number of data points per revolution, and then multiplied by two to get the average diameter.

Eccentric Shafts

As pivotal parts of steam locomotives and other engines, eccentrics must be measured to the kind of high standards for which Adcole gages are specifically designed.

Electric Vehicle (EV)

Feature/Locator Presence

Adcole gages provide extremely accurate feature/locator presence

measurements, enabling manufacturers to maintain strict quality control standards.

Flatness

Flatness is measured using a height gauge run across the surface of the part where the reference feature is held parallel, being certain that any point along the surface does not go above or below the tolerance zone. Adcole gages deliver sub-micron measurement accuracies, providing 3D measurement about the length and width of the part — ensuring the entire surface is in tolerance.

Gage Accessories

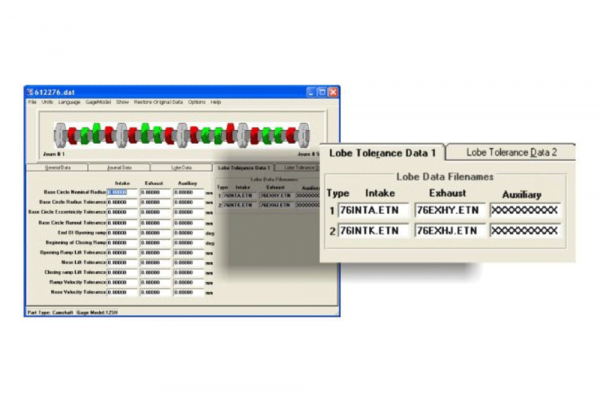

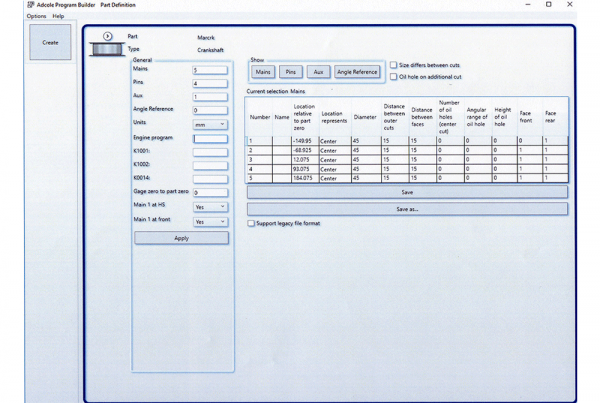

Gage Software

Gears

Tolerances and standards for gears grow tighter every year. Adcole’s gages are specifically designed to accommodate these high standards.

Gears & Transmission Shaft Gages

When it comes to quality assurance, engineers expect durable, reliable metrological solutions. Adcole gages are relied on worldwide for in-depth analysis of gears and transmission shifts.

Heavy Diesel Camshafts & Crankshafts

Adcole’s gages are just as reliable for measuring heavy diesel machine parts as they are for standard automobiles.

Heavy Diesel Equipment

Heavy Diesel manufacturers select Adcole automated CCMM gages because they provide the extreme length and mass capacity necessary to ensure that high value powertrain components meet strict quality standards while reducing or eliminating manual inspection techniques.

High Precision Shaft Gages

At Adcole, precision is prized. These gages offer the world standard in precise, accurate data to ensure quality, efficiency and reduced cost on the manufacturing floor.

Horizontally Loaded Shaft Gages

Our horizontally loaded gages use revolutionary 3D software to provide precise, high speed measurements of complex features.

Hydraulic Rings

Using Adcole gages, hydraulic pump rings can be measured with the industry standard in precision, efficiency, and ease, freeing up your work force and saving time.

In-Line Shaft Gages

Adcole’s ln-line camshaft measuring machines have brought audit room measurement accuracy to the production line.

Industrial

Heavy industry organizations facing manufacturing tolerance challenges choose Adcole’s accurate, flexible and durable gaging solutions for laboratory or production floor settings.

Length

Length is a measured dimension of an object. Adcole gages deliver part length data to within 10-12 millionths of an inch (0.25 μm).

Locomotive Engine & Rail

To meet the industry demands for extreme durability and efficiency of their products, Locomotive Engine and Rail manufacturers must deliver large yet high-precision components made to exacting standards. That’s why they rely on Adcole to supply solutions with high accuracy and the length and mass capacity needed for these challenges.

Marine

With a full complement of technologies for marine manufacturers, Adcole provides flexible metrology solutions for products ranging from recreational outboard engines to ocean freighter powertrains to ensure the utmost durability and reliability on the water.

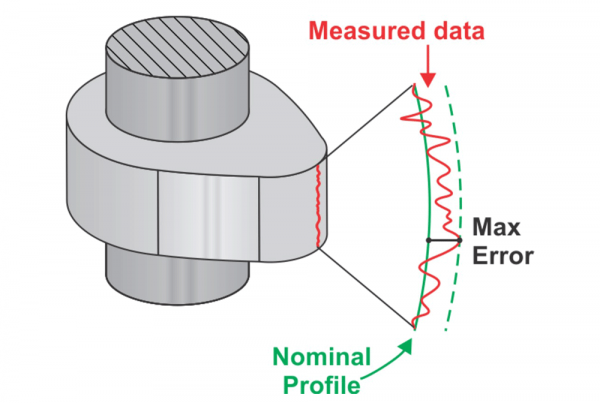

Max Height of Profile

The maximum height of profile is defined on the sampling length: like the average maximum height of profile, this measurement is typically used to check whether the profile has protruding peaks that might affect static or sliding contact function of a component.

Max Peak Depth of Profile

The maximum peak depth of a profile is the depth of the deepest valley from the mean line of the component profile, as defined on the sampling length.

Max Peak Height of Profile

The maximum peak height of profile is the height of the highest peak from the mean line of the component profile, as defined on the sampling length.

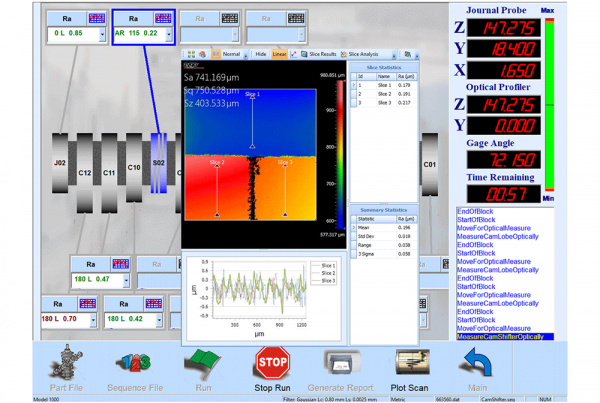

Metrology Software + 3D Mapping

Adcole provides comprehensive metrology software for enhanced measurement analysis. Powerful productivity suites allow for in-depth measurement analysis and straightforward gage operation, from 3D mapping software to simplified gage programming with Adcole’s Program Builder.

New Energy Vehicles

Battery Electric and Plug-In Hybrid manufacturers select Adcole NEV gages because they offer fast inspection speeds, and provides a flexible platform for performing audit gage or high-speed production gage tasks.

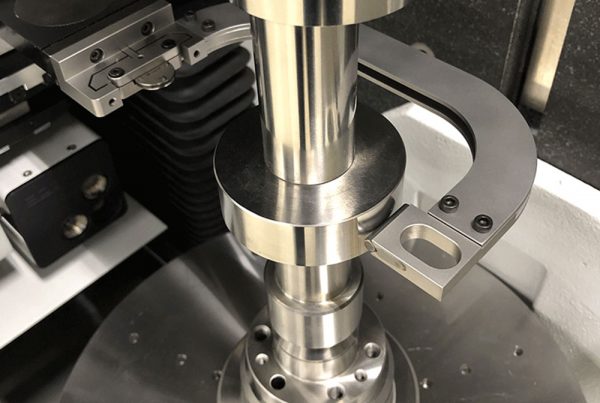

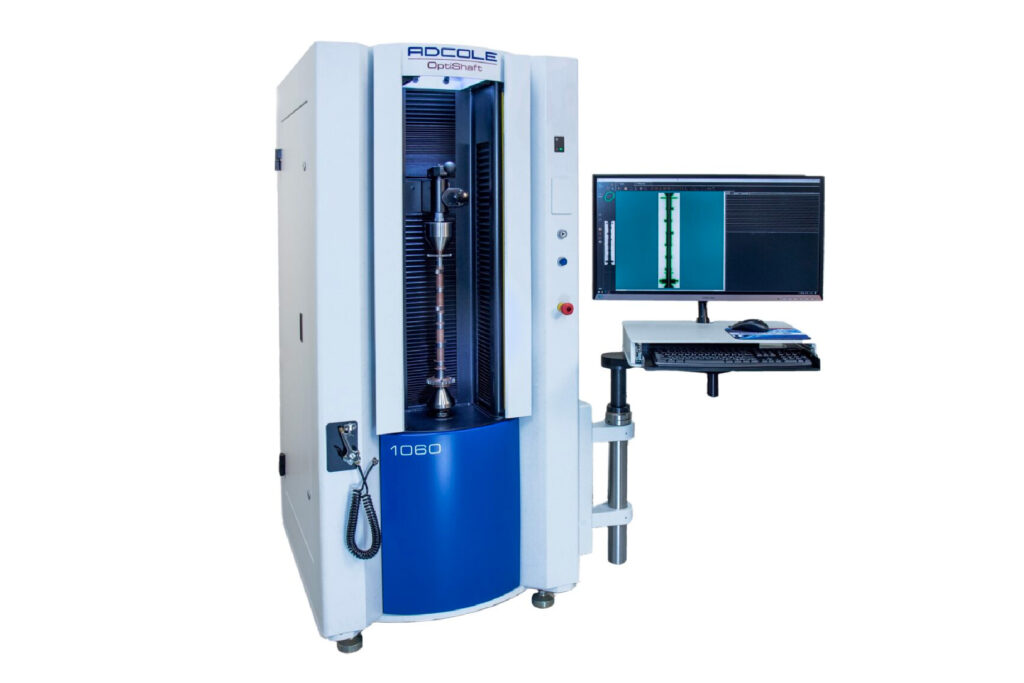

Optical Non-Contact Shaft Measuring Systems

Our optical metrology probes and systems enable engineers to quickly identify and solve manufacturing problems. Adcole gages are renowned for their durability, providing shop floor ruggedness while delivering the highest performance for close tolerance measurements.

Optical Shaft Gage

Parallelism

Measured parallelism, sometimes called journal parallelism, is based on the radial measurements of the two outside cuts of the journal.

Perpendicularity

Perpendicularity is based on the strain gage and carriage readings taken over a full revolution. The perpendicularity calculation is based on the difference between the face axis and reference axis

Pistons

Adcole’s rugged gages, such as the Model 911, are designed to measure pistons and other cylindrical components in the most demanding production environments.

Power Generation

The power generation market has unique application needs: maximum uptime, dependable technology, durable components that must function in harsh industrial environments. Adcole gages and software offer the assurance that power generation manufacturers can meet these needs.

Precision Hydraulic Cylinders

Advanced 3D part mapping allows engineers to visualize precision hydraulic cylinders in intricate detail.

Profile

Profile defines a uniform boundary around a surface within which the elements of the surface must lie. Profile simultaneously controls a feature‘s form, size, orientation, and location.

Pump Lobes

Pump lobes are relied upon in machines across a wide variety of industries, making it vital for you to have accurate, in-depth measurements of these essential parts.

Pumps & Compressors

Pump & Compressor fabricators require a flexible gaging solution that covers a wide range of products and production volumes. That’s why Pump & Compressor manufacturers select Adcole automatic CCMMs to ensure that high quality standards are being met and the resulting assurance that their components offer a long service life. With unparalleled gage capacities, Adcole has even the largest pump and compressor manufacturers covered.

RMS Roughness

Roughness average is an average taken from measuring the surface texture of a component. It is quantified by the deviations in the direction of the normal vector of a real surface from its ideal form. If these deviations are large, the surface is rough; if they are small, the surface is smooth.

Robot Loaded & Fully Automatic Shaft Gages

Not only do Adcole’s robot loaded, fully automatic gages save your company time, they free up engineers so they can focus on other pivotal projects.

Robotic Shafts

Adcole’s engineers understand the exceptionally tight tolerances that robotic shafts and reducers must meet, which is why our gages are capable of repeatable, sub-micron precision.

Robotics

Robotics manufacturers need extremely precise, repeatable processes to meet exacting product specifications and part matching/classification requirements — whether on the shop floor or the inspection lab, Adcole’s gages provide the assurance that these requirements are met.

Roughness Average

Rely on our world standard laser measurement technology to inform you of imperfections on a microscopic scale, saving your team valuable time spent troubleshooting.

Roughness Shaft Gages

Adcole introduced the very first semi-automatic surface roughness gages for production. The robust construction and anti-vibration technology provide highly accurate surface roughness measurements, even in harsh production environments.

Roundness

Roundness is defined as the difference between the maximum radius (Rmax) and the minimum radius (Rmin) relative to the least squares center of a single radial measurement.

Runout

Runout is based on a single radial measurement and is defined as the difference between the maximum radius (Rmax) and the minimum radius (Rmin) relative to the reference axis.

Sliding Camshafts

Combined with Adcole’s groundbreaking independent, opposed measuring heads, our touch-screen interface makes diagnostic routines and part identification of sliding camshafts easier than ever before.

Small Engine & Appliances

Small Engine & Appliance manufacturers seeking an automated, high speed inspection system with a strong return on investment choose Adcole CCMM gages.

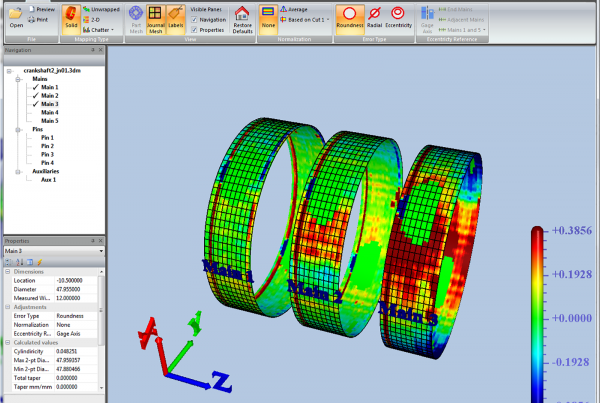

Straightness

Straightness is defined as the difference between the maximum positive deviation (Rmax) and the maximum negative deviation (Rmin) , relative to the Least Squares line of a single vertical measurement.

Surface Finish

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane).

Taper

Taper is a determination of angle and form errors on the outside and inside tapers, and parts with angular surfaces.

Throw/Stroke

The crank throw is a measure of the distance from the center-line of the main journal to the center-line of the rod journal. This distance could be considered the radius of the crank arm. Twice this measurement provides the stroke of an engine.

Transmission / Output Shafts

Across industries, Adcole gages are relied upon to keep your engines’ most essential parts—such as transmission and output shafts—running safely and efficiently.

Transportation/Trucking

Transportation and Trucking manufacturers select Adcole automated CCMM gages because they provide the extreme length and mass capacity necessary to ensure that high value powertrain components meet strict quality standards while reducing or eliminating manual inspection techniques.

True Position

The True Position is the exact coordinate, or location defined by basic dimensions or other means that represents the nominal value. The “Position” Tolerance is how far your features location can vary from its “True Position”.

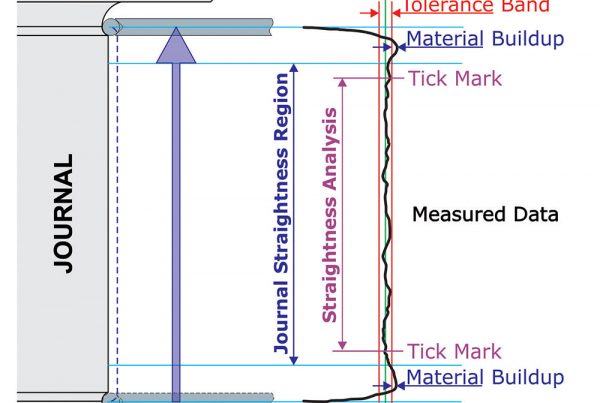

Turbochargers

Reduce scrap and rework of turbochargers through the use of Adcole’s patented pattern recognition technology.

Vertically Loaded Shaft Gages

Adcole’s vertically loaded gages use highly sophisticated sensors to ensure accurate read-outs.

Width

Width is the horizontal measurement taken at right angles to the length. Adcole gages deliver sub-micron accuracy and repeatability of width parameter measurements.

- All

- Aerospace

- Angularity

- Automated Gage Systems

- Automotive

- Axial Location

- Axles

- Cam Lobe Lift Error

- Camshafts

- Center Deviation

- Chatter

- Concentricity

- Crankshaft & Camshaft Measuring Gages

- Crankshafts

- Custom Shaft Gages

- Cylindricity

- Diameter

- Eccentric Shafts

- Electric Vehicle EV

- Feature/Locator Presence

- Flatness

- Gage Accessories

- Gage Software

- Gears

- Gears & Transmission Shaft Gages

- Heavy Diesel Camshafts & Crankshafts

- Heavy Diesel Equipment

- High Precision Shaft Gages

- Horizontally Loaded Shaft Gages

- Hydraulic Rings

- In-Line Shaft Gages

- Industrial

- Length

- Locomotive Engine & Rail

- Marine

- Metrology Software + 3D Mapping

- New Energy Vehicles

- Optical Non-Contact Shaft Measuring Systems

- Optical Shaft Gage

- Parallelism

- Perpendicularity

- Pistons

- Power Generation

- Precision Hydraulic Cylinders

- Profile

- Pump Lobes

- Pumps & Compressors

- Robot Loaded & Fully Automatic Shaft Gages

- Robotic Shafts

- Robotics

- Roughness Shaft Gages

- Roundness

- Runout

- Sliding Camshafts

- Small Engine & Appliances

- Straightness

- Surface Finish

- Taper

- Throw/Stroke

- Transmission / Output Shafts

- Transportation/Trucking

- True Position

- Turbochargers

- Vertically Loaded Shaft Gages

- Width