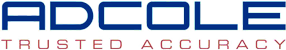

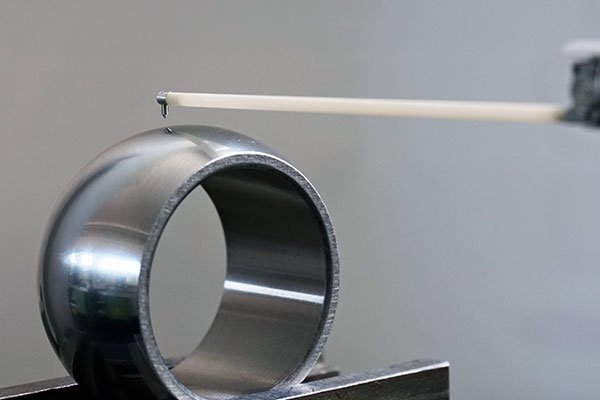

The Adcole 1200-DH gage provides manufacturers with the ultimate metrology tool for production floor or metrology laboratory use with increased throughput. As a part of Adcole’s flagship 1200 product lines, the 1200-DH makes use of a laser interferometer for the ultimate in measurement precision and accuracy. The addition of a second measuring head significantly reduces cycle time, and the gage can be automated to allow for robot loading for 100% inspection in the production line.

Available in multiple sizes to allow for part length capacities of up to 1500mm.