Camshaft and Crankshaft manufacturers are all too aware of the frustrations that unwanted vibrations can cause on a production line. Hours, days, weeks can be lost as engineers try to determine the root cause of a vibration — and the resulting undesirable tool marks — on a high value precision part.

Reviled in the industry, this undulating pattern of marks on a machined surface is known as chatter. Chatter marks are caused by the vibration of a cutting tool or grinding wheel as the workpiece material is cut to craft a complex rotating part like a camshaft or a crankshaft.

It’s very difficult to prevent an issue that your organization can see only after the part is made. What manufacturers need is a flexible solution that will collect and analyze dimensional data to pinpoint machining/grinding process issues before producing out of spec components.

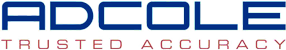

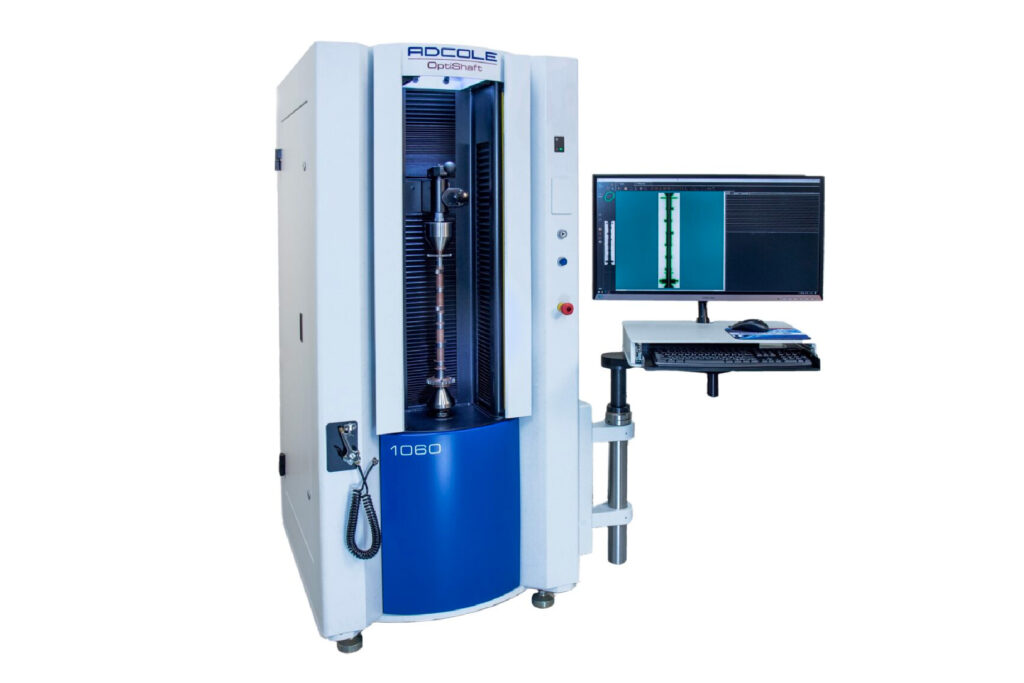

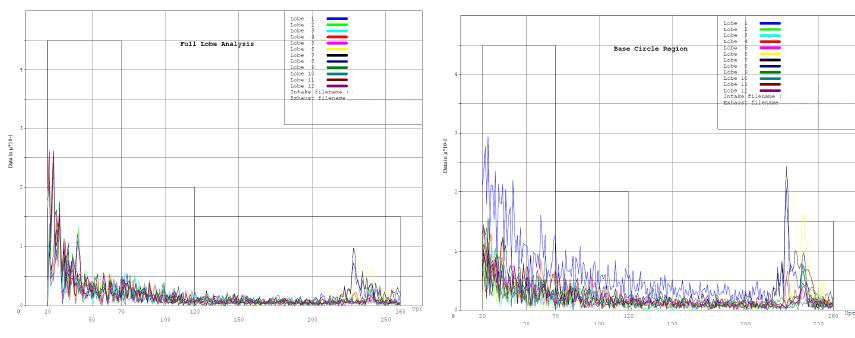

That’s why Adcole offers the FFT Chatter Analysis Software package. The software package includes features such as frequency analysis of error data over a specified UPR range using standard single or multi-region box tolerances, or a tolerance curve based on a formula or file. Chatter Analysis Software allows users to look at full 360° data set, or at a specific angular region within the error file.

Using FFT Chatter Analysis software, organizations can monitor and optimize their manufacturing process — thereby improving efficiency, reducing costs and maximizing grinder uptime. Moreover, the software provides actionable data that helps your organization enhance your manufacturing process, and find manufacturing efficiencies that improve profitability.

Tired of chasing chatter gremlins in your production line? Learn more about Adcole FFT Chatter Analysis Software here.