Zum Einrichten eines Werkstücks muss der Benutzer nur die Merkmale auswählen, die ausgegeben werden sollen. Das Programm erstellt die Messsequenz. SPC- und Ausgabeprotokollvorlagen werden ebenfalls erzeugt.

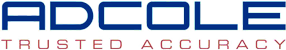

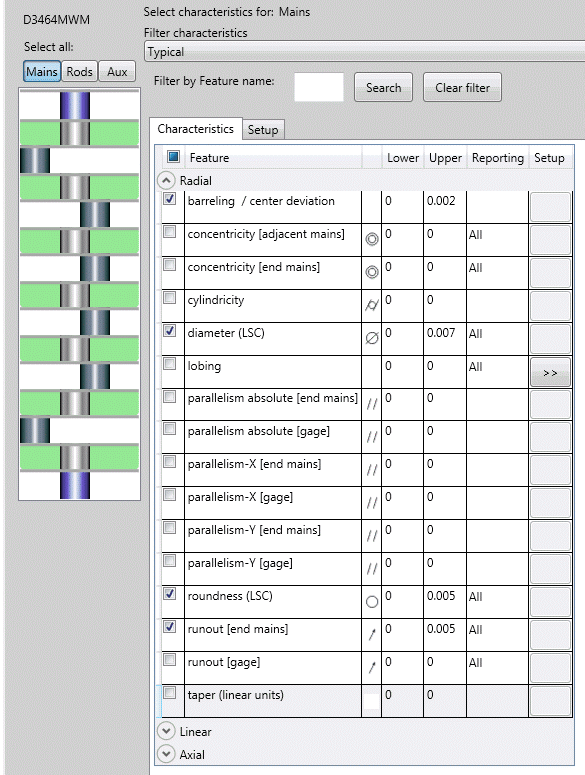

Wie Sie in der Abbildung sehen können, können einzelne Messparameter auf Teileelemente angewendet werden, indem Sie das entsprechende Kontrollkästchen aktivieren. In diesem Beispiel haben wir die Hauptlager-Toleranzen für Balligkeit, Durchmesser, Rundheit und Rundlauf bis zum Endlager definiert. Diese Merkmale werden dann auf dem im Ausgabeprotokoll auf der Messmaschine angezeigt. Da wir Hauptlagermerkmale definieren, werden alle Hauptlager in Grün in der Teiledarstellung angezeigt.

Sie können dieses Dienstprogramm auch an Ihre Anforderungen anpassen. Wenn Sie über eine Reihe Merkmale regelmäßig messen oder die verfügbaren Optionen einschränken möchten, können Sie eine benutzerdefinierte Merkmal-Liste erstellen und speichern. Dies kann nützlich sein, um Arbeitsfolgen zu sortieren und Programme für neue Teile zu erstellen.

Auswahlen und Eingaben können für ähnliche Teile oder für ähnliche Operationen wiederverwendet werden. Gespeicherte Formate werden in eine XML-Datei geschrieben.

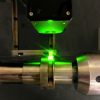

Die neue Schnittstelle ist derzeit für neue ADCOLE 1100- und 1200-Messmaschinen-Modelle verfügbar und kann bei älteren Maschinen nachgerüstet werden. Andere Messmaschinen-Modelle und Nockenwellenanwendungen sind derzeit in Entwicklung. Um eine Demonstration der neuen ausgabeorientierten Schnittstelle von ADCOLE zu sehen und Ihre Upgrade-Optionen zu besprechen, wenden Sie sich bitte an Ihren Vertriebsmitarbeiter oder senden Sie eine E-Mail an sales@adcole.com.