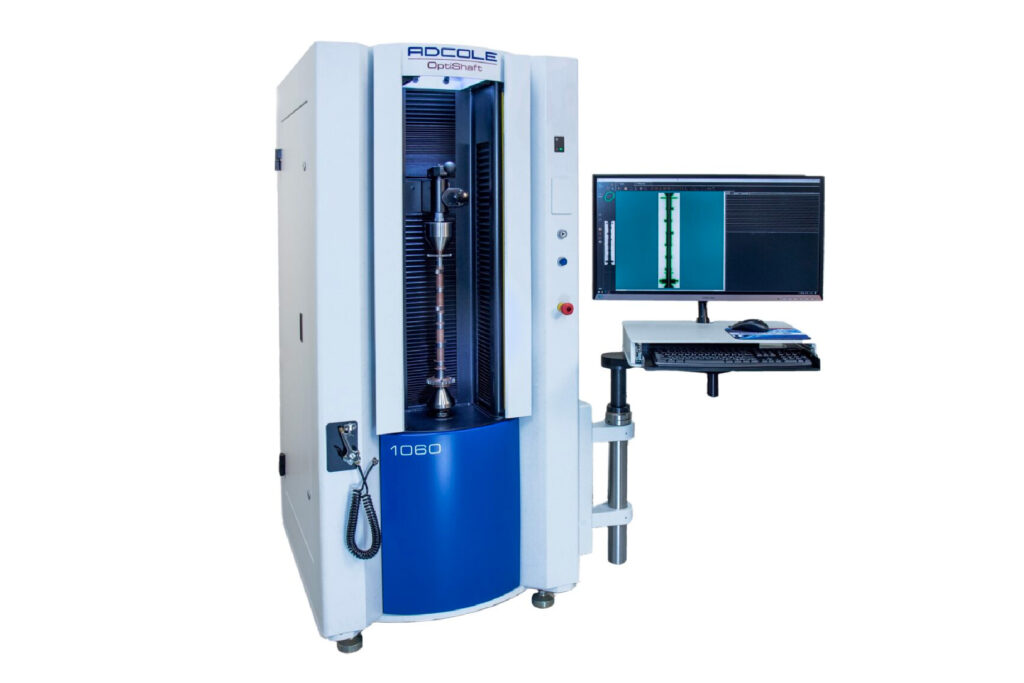

Manufacturers seeking a rapid, extremely precise gage for inspection of high-value parts like camshafts, crankshafts, pistons and other cylindrical component need look no further than the premier Adcole 1200-LX gage. The 1200-LX is a class-leading dimensional gage, owing to laser interferometer technology that drives some of the industry’s most impressive accuracy values. The 1200-LX delivers submicron accuracy and repeatability, including: 0.005 μm radial resolution, headstock runout <0.1 μm, ± 0.25 μm radial accuracy, and ± 1.0 μm/100mm axial accuracy.

In addition to the state-of-the-art accuracy the gage imparts, the 1200-LX can manage large and heavy components, too. The gage offers maximum part length sizes of 1000mm (39.37” – 1200-LX 1 meter) and 1500 mm (59.06” – 1200-LX 1.5 meter) respectively — with a maximum part weight of 340 kg (750 lb.)

The newly redesigned 1200-LX shipped after 2 years of extensive engineering efforts to build the best CCMM available today. The redesigned gage offers a smaller footprint featuring a single cabinet design, and updated electronics and hardware that uses a single central processing unit (CPU). The 1200-LX utilizes a new z-axis servo motor and linear motors for the follower axis, plus a higher resolution laser that powers state-of-the-art measurement accuracies. Customers taking delivery of the 1200-LX gage have complimented the gage’s compact design, comfortable ergonomic features and the rich set of highly accurate metrology data that the gage can glean from intricate part geometries.

The rich data set that the 1200-LX gage can provide manufacturers includes these measurement parameters:

- Angularity

- Cam Lobe Lift Error

- Center Deviation

- Chatter

- Concentricity

- Cylindricity

- Diameter

- Flatness

- Length

- Parallelism

- Perpendicularity

- Profile

- Roundness (Circularity)

- Runout

- Straightness

- Taper

- Throw/Stroke

- True Position

Manufacturers serving the automotive, aerospace, heavy diesel equipment, industrial, locomotive engine & rail, marine, power generation, transportation and trucking marketplace understand the value that an Adcole gage brings to their manufacturing process. The 1200-LX is delivered in a smaller gage footprint that saves valuable production floor space. The swivel-hinge mounted control panel provides ergonomic, convenient positioning. Brushless and linear slide motors supply more torque and speed, reduce friction, and improve measurement accuracy.

The gage is available with an optional enclosed measuring chamber with interlocking, easy-swing door that ensures a clean gage measurement environment. The 1200-LX includes a Go/No-Go LED indicator that shows pass/fail of the part. The 3D Color Map and Program Builder software data analysis provides reporting, including part summary, part programming, inspection packages, dimensions, calculated values for elements.

To learn more about the 1200-LX gage, check the gage out here.