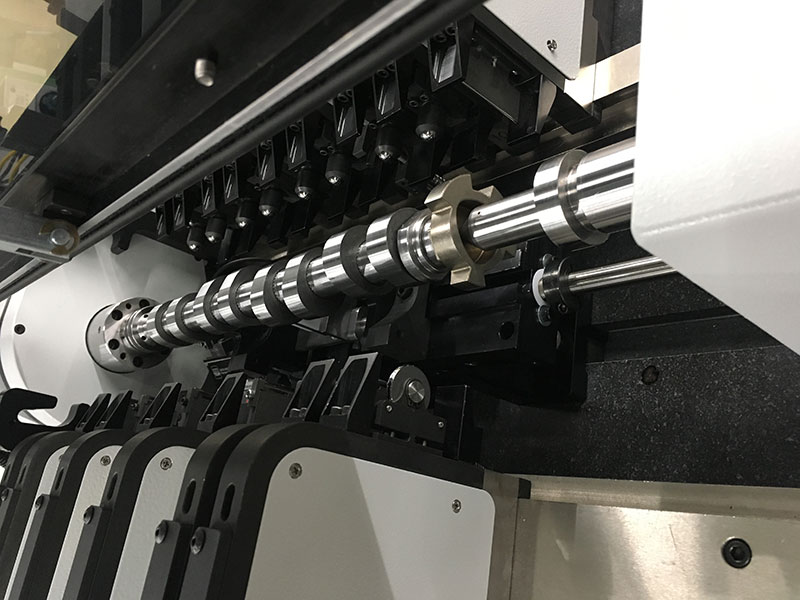

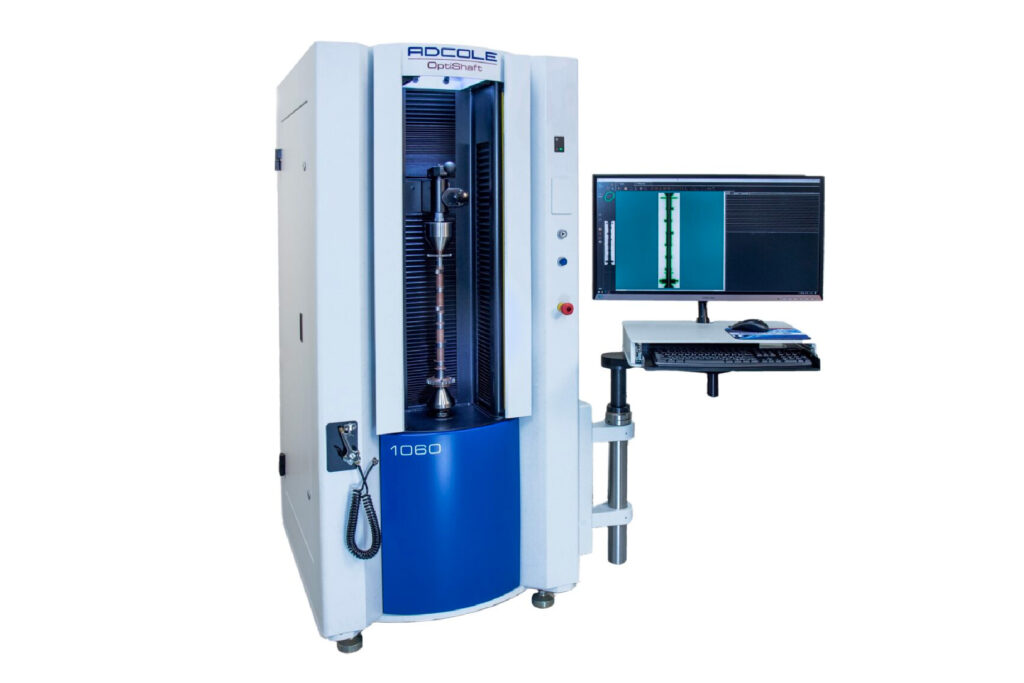

Adcole is proud to showcase a robust software solution that provides a solution to the challenge of accurately sourcing chatter “bursts” on high-value crankshafts and camshafts. Introducing the Real Time Chatter Analysis – Sliding Window Software, a chatter analysis software that allows manufacturers to realize the power of angular window (or sliding window) analysis (in degrees) for camshaft and crankshaft quality control tasks. This software solution enables engineers to detect chatter that occurs in only a small angular window of the journal or lobe surface (burst chatter), without diluting the amplitude by analyzing over a larger angular window or over the entire 360⁰.

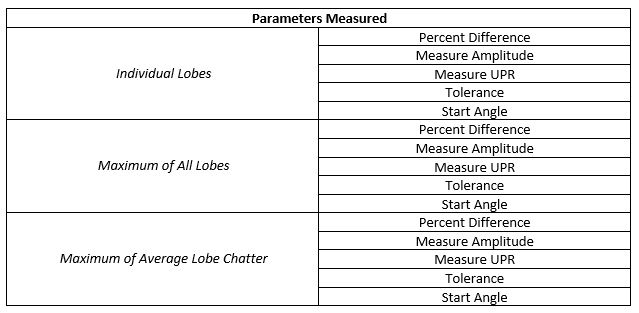

Real Time Chatter Analysis – Sliding Window Software (RTCA-SW) software enables engineers to measure these parameters:

Chatter Burst Analysis

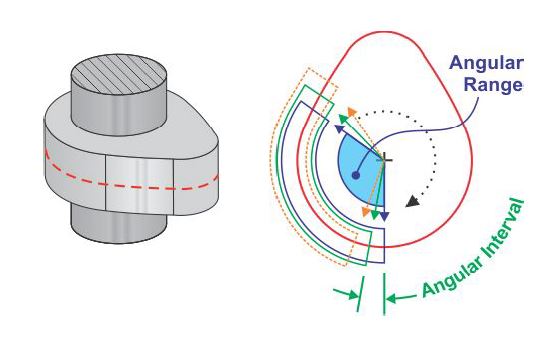

Manufacturers facing chatter burst issues can leverage the power of data collection using 120⁰ amplitude measurements over three distinct sections of a camshaft or crankshaft. Using this feature in tandem with your Adcole gage, you can analyze specific degree segments across the lobe, moving in specific degree increments. The RTCA-SW software is available for individual lobe analysis and for average lobe FFT chatter analysis. The data gleaned from this option is saved based on a percentage of tolerance or on a strict value difference.

Adcole uses a sliding window approach to provide a more thorough data set than the traditional base circle measurement technique. For example, instead of providing a 120⁰ amplitude measurements over three distinct sections of a component, the RTCA-SW offers engineers the ability to obtain the maximum amplitude captured across the entire chatter “burst” in the 120⁰ windows. The measured angle is in the center of the window, and engineers can move the window gradually as they wish (Adcole recommends 30⁰ of movement per each sliding window of data) to obtain a very detailed data set about chatter issues across as much of a camshaft or crankshaft as necessary.

About Chatter

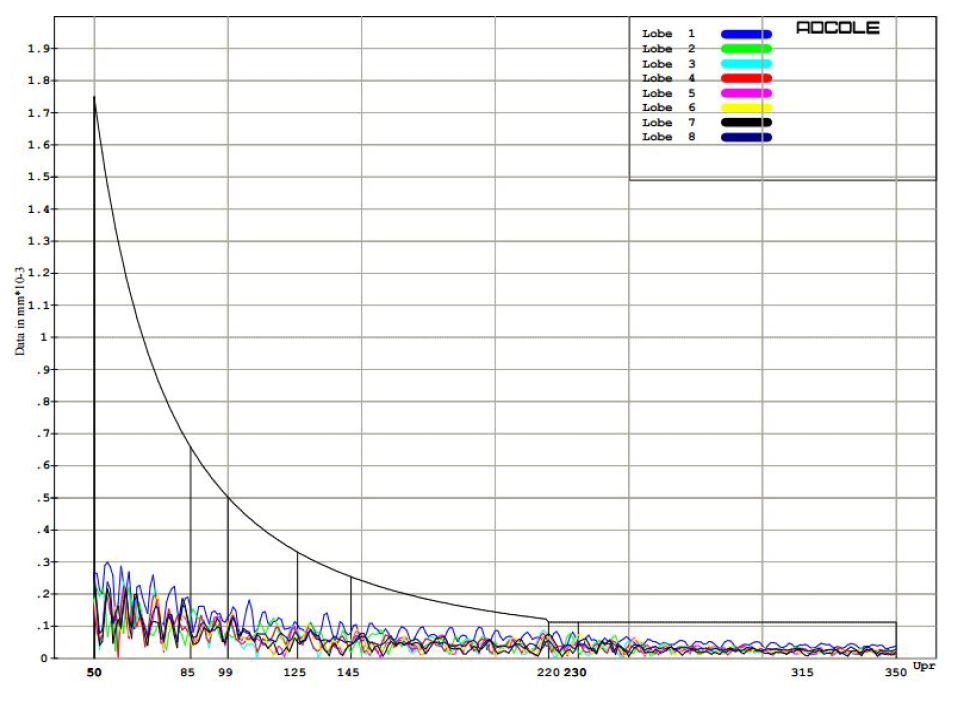

Chatter is the undulating pattern of marks on a machined surface, usually caused from the vibration of the grinder. Adcole Chatter Analysis software detects high frequency vibrations in unfiltered lobe error, or journal roundness error, and determines the measured amplitude at each specific frequency or undulations per revolution (UPR). The report from this analysis is useful in troubleshooting and correcting manufacturing issues prior to parts being out of specification. This process monitoring tool helps to prevent out of specification components from getting into the supply chain. FFT Chatter Analysis Software provides highly accurate data and graphical outlet reports with the choice of outputs expressed as measure amplitude (µm or nm) to Undulations Per Revolution (UPR).

Benefits of Real Time Chatter Analysis – Sliding Window Software

Organizations that use the RTCA-SW solution are able to find chatter “bursts” on camshaft and crankshaft components. The RTCA-SW option affords the data needed to find machining issues, and with deeper analysis over time, create a predictive analysis process that improves overall camshaft and crankshaft production. Sliding window technology provides the means for tracking chatter across the entire lobe surface in customizable detail.

In addition, the RTCA-SW solution reports the specific angle that the chatter is found, providing a very specific data set about your grinding machining process. Lastly, the software offers a practical means for manufacturers to obtain a rich data set about pin journals on crankshafts.

Features of Real Time Chatter Analysis – Sliding Window Software

The RTCA-SW environment provides separate chatter plots about each lobe, plus a plot of the average of all the lobes. The data is displayed in a curved tolerance graph that clearly shows individual lobe data and the overall lobe trend. The programmable “sweep” option enables users to measure a specific angular range, and specify the incremental angular window (sliding window) to obtain a 120⁰ snapshot of a given part (Adcole recommends sliding windows of 30⁰). Furthermore, the RTCA-SW solution offers the means for metrology professionals to see amplitude in its full impact, unmitigated by the scanning range of the component.

To learn more about Real Time Chatter Analysis – Sliding Window Software, click here.