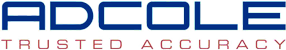

Straightness is a tolerance that controls the form of a line somewhere on the surface or the feature. Incremental straightness looks at lobing the linear data occurring in a specified interval over the distance of a scan.

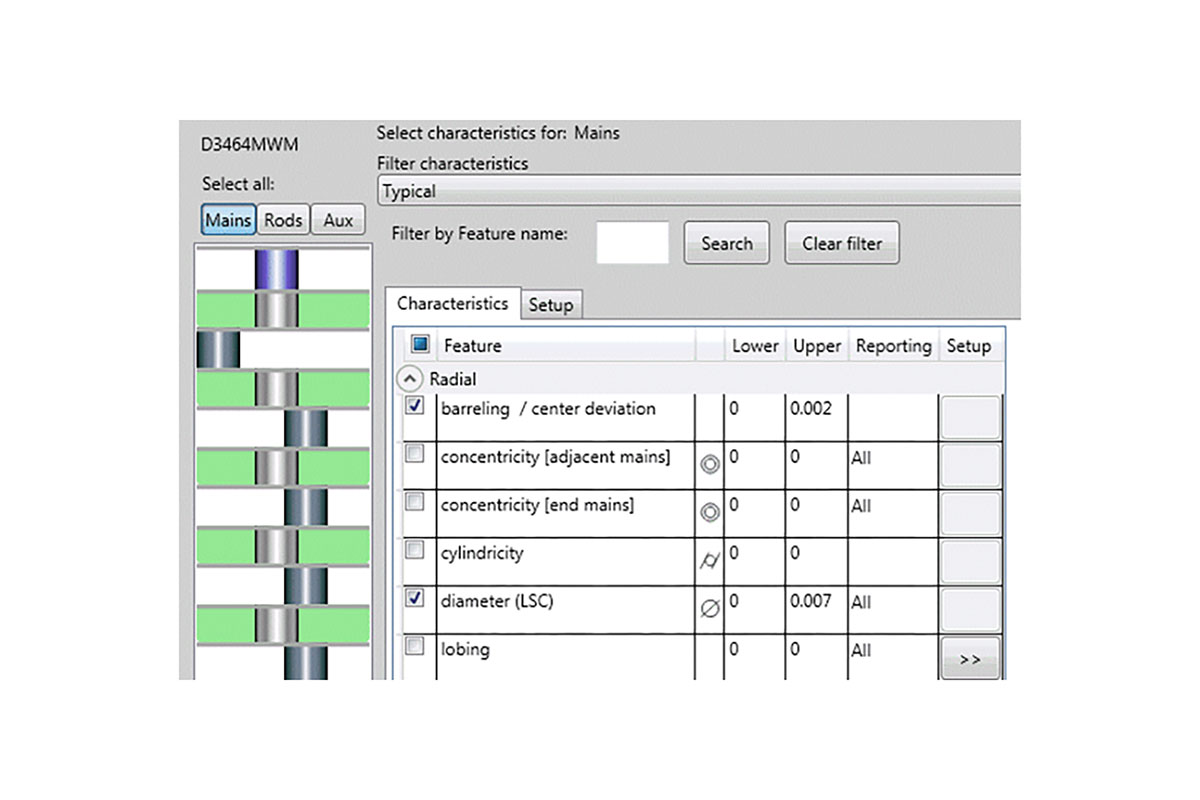

Adcole Advanced Straightness Software extends the ability to use a sliding window of a specified length to determine the largest peakto- valley error and the location in the scan data that it occurred.